Department of Macromolecular Compounds Chemistry

Functional polysiloxanes and silicone-based materials

Short URL for media go.spbu.ru/rgislamova

Research Team

The Head of the Research Team

|

Islamova ReginaDoctor of Chemical Sciences, Professor This email address is being protected from spambots. You need JavaScript enabled to view it. |

Research Staff

|

Deriabin KonstantinPhD This email address is being protected from spambots. You need JavaScript enabled to view it. |

|

Miroshnichenko AnnaThis email address is being protected from spambots. You need JavaScript enabled to view it. | This email address is being protected from spambots. You need JavaScript enabled to view it. |

PhD students

|

Golovenko EkaterinaThis email address is being protected from spambots. You need JavaScript enabled to view it. | This email address is being protected from spambots. You need JavaScript enabled to view it. |

Students

|

Gorodnyaya ElenaThis email address is being protected from spambots. You need JavaScript enabled to view it. |

|

Kocheva AnastasiaMaster student This email address is being protected from spambots. You need JavaScript enabled to view it. |

|

Parshina ElizabethBachelor student This email address is being protected from spambots. You need JavaScript enabled to view it. |

Former students and staff

|

Antonov NikitaThis email address is being protected from spambots. You need JavaScript enabled to view it. |

|

Baranovskiy Egor |

|

Besedovsky Makar |

|

Dobrynin MikhailPhD |

|

Godunov Pavel |

|

Ignatova Nina |

|

Lobanovskaya Ekaterina |

|

Mongilyov Ilya |

|

Philippova SofyaMaster student This email address is being protected from spambots. You need JavaScript enabled to view it. |

|

Ponomareva AnnaBachelor student This email address is being protected from spambots. You need JavaScript enabled to view it. |

|

Rashevskii ArtemMaster student This email address is being protected from spambots. You need JavaScript enabled to view it. |

Research Projects #1

Basic silicone rubbers and materials based on them

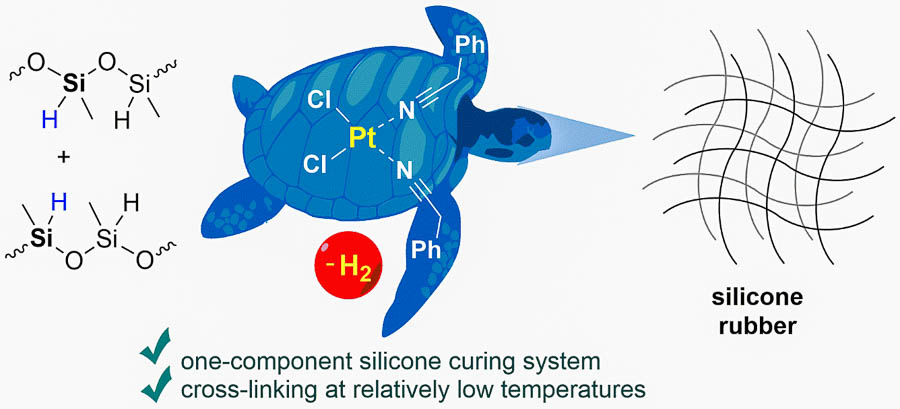

1. Hydrosilylation of polysiloxanes by new platinum group catalysts

Hydrosilylation of alkenes is the key reaction for obtaining industrially important organosilicon compounds. Catalytic hydrosilylation is especially important for polysiloxanes cross-linking and obtaining rubbers with useful properties, such as high and low temperature resistance, good electrical insulation, radiation resistance, oil- and petrol-resistance at increased temperatures, high chemical and biological inertness, environmental safety, etc.

We search and develop effective hydrosilylation catalysts and we create new polymer compositions with improved characteristics based on them.

At the moment we suggested relatively cheap, accessible, effective and in the same time selective platinum group catalysts as alternative to Karstedt’s catalyst that is used in most part of industrial processes of polysiloxane cross-linking.

Our platinum catalysts allowed to obtain composition “smart plasticine” for modelling, copying, making crafts and cast molds of different objects and surfaces.

- Molecules. 2016. V. 21. P. 311-321. DOI:10.3390/molecules21030311.

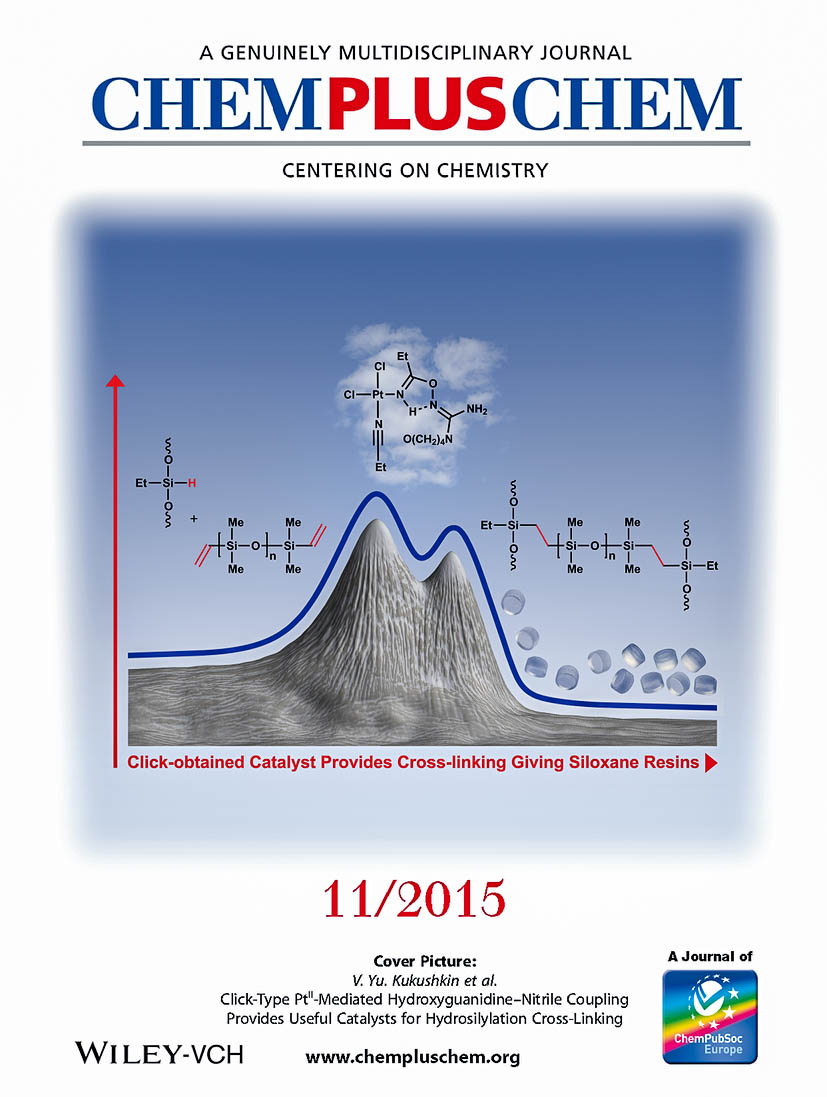

- ChemPlusChem. 2015. V. 80, N 11. Р. 1607-1614. DOI: 10.1002/cplu.201500327.

Patent RU No. 2579143 С1 (14.04.2015).

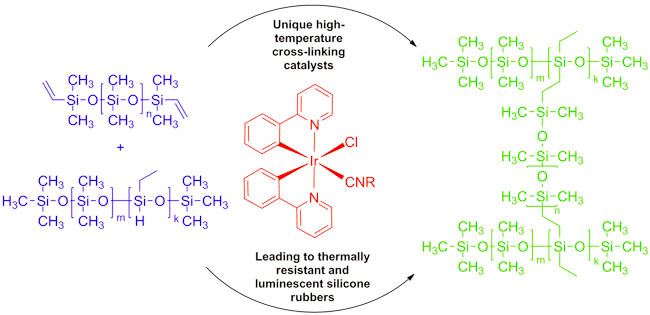

Thermally stable and luminescent silicone rubbers were obtained with new iridium catalysts. It allows creating silicone coatings with controllable thickness and substantially extends potential application of such materials (including special coatings for passive thermal control systems in spacecraft (DOI:10.1007/978-3-319-19309-0_5).

Catalysis Science & Technology. 2017. V. 7. No. 24. P. 5843-5846. DOI: 10.1039/c7cy02013a.

Patent RU No. 2579117 C1 (10.03.2015).

Interview of Regina Islamova for cultural & political magazine “E-vesti”

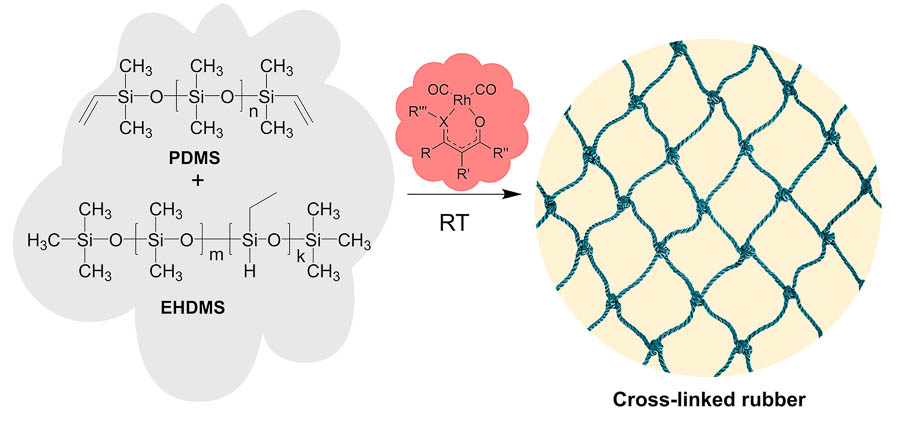

We proposed rhodium catalysts that allow to obtain high-elasticity silicone rubbers at room temperature without defects (cracks, bubbles).

Journal of Catalysis. 2019. V. 372. P. 193–200. DOI: 10.1016/j.jcat.2019.03.004.

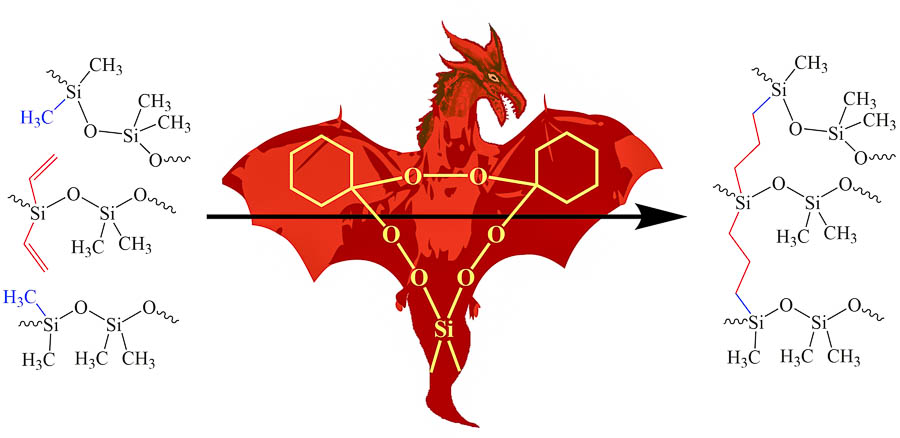

2. Peroxide curing of polysiloxanes

Peroxide curing at elevated temperatures (> 100 °C) is alternative to catalytic hydrosilylation for producing cured silicone rubbers. However, the use of traditional organic peroxides as sources of free radicals leads to the formation of mechanically unstable silicone rubbers (without fillers) with structural defects due to the evolution of gaseous products. An addition of inhibitors into reaction mixture complicates the process and contributes to impurity of the obtained product. The search for new initiators of peroxide curing, which both are structurally similar to silicones and allow solving the above problems, is relevant task. Together with laboratory for studies of homolytic reactions (N.D. Zelinsky Institute of Organic Chemistry, Moscow) we have proposed and studied new vinyl-selective organosilicon peroxides, which were used to obtain antibacterial silicone rubbers with improved mechanical characteristics without using inhibitors at (150–200) °C.

New Journal of Chemistry. 2018. V. 42. No. 18. P. 15006–15013. DOI: 10.1039/C8NJ02499E.

Research Projects #2

Hybrid polysiloxanes and materials based on them

1. Hybrid polysiloxanes and materials based on them

Development of effective methods for synthesis of new smart and “super-smart” polymers and creation of new materials and devices based on them is related to Targeted Programme for Research and Development in Priority Areas of Development of the Russian Scientific and Technological Complex as well as they are relevant tasks of modern chemistry.

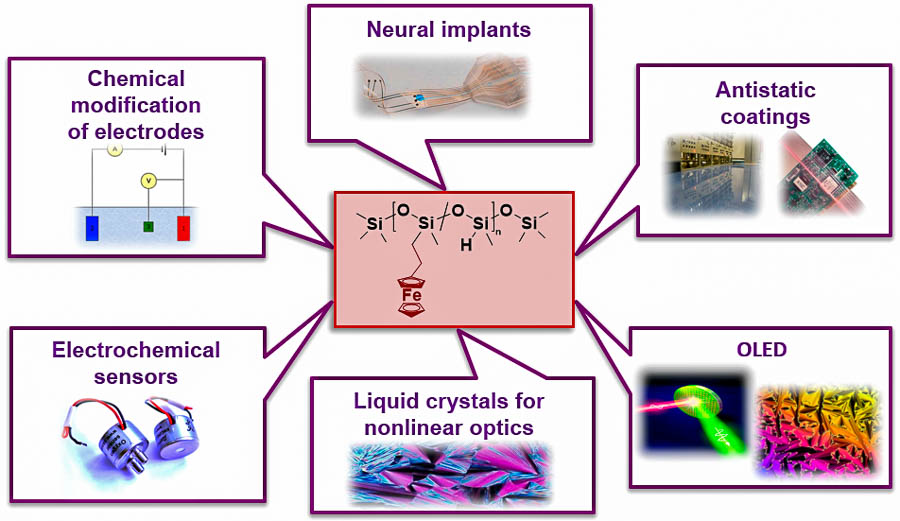

We synthesize novel hybrid metal-containing (co)polysiloxanes (remarkable due to electrically conductive fragments in its structure) for creation of flexible electrochemical sensors, biosensors, molecular electronic devices, liquid crystals in non-linear optical systems and others.

At the moment we have obtained unique ferrocene-containing silicones, which found its application as materials for medical neural implants, that help to cure serious neurological diseases and training of damaged functions (motor activity, visceral systems, sight, hear) (together with prof. P.E. Musienko, Institute of Translational Biomedicine SPbU).

Grant RFBR No. 18-33-20062. Project: «Guided synthesis and properties of electrically conductive silicone materials for medical neural implants» (grant owner: Islamova R.M.). 2019-2020.

- Applied Organometallic Chemistry. 2019. DOI: 10.1002/aoc.5300.

- Organic & Biomolecular Chemistry. 2019. V. 17. Р. 5545-5549. DOI: 10.1039/C9OB00791A.

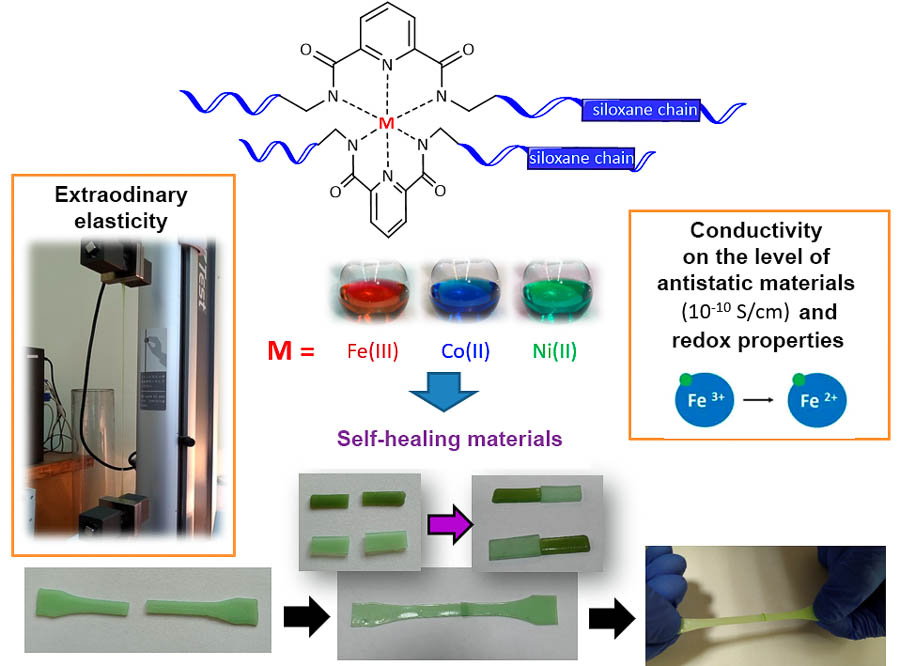

2. Self-healing silicone materials

Self-healing materials are one of the perspective and fast developing fields of material science. Self-healing polymers are necessary for creation of super flexible sensors, actuators and stimuli-sensitive materials (including artificial skin or “second skin”), additive technologies and other flexible devices.

We synthesize complexes of (co)polysiloxanes and metal centers (iron, nickel, cobalt, etc.) and use them to make self-healing elastomers and stimuli-sensitive materials, which can be used for creation of artificial muscles (Nature Chem. 2016. 8, No. 6. >618–624), as well as for flexible sensors (Adv. Sci. 2019. 1900186).

Grant RFBR No. 19-33-90134. Project: «Synthesis and research of complexes of (co)polysiloxanes with electroactive centers as self-healing materials» (Islamova R.M., Deriabin K.V.). 2019–2021.

- Polymer. 2021. V. 212. P. 123119. DOI: 10.1016/j.polymer.2020.123119.

- Organometallics. 2021. V. 40(15). P. 2750–2760. DOI: 10.1021/acs.organomet.1c00392.

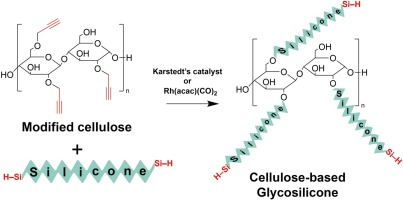

3. Glycosilicones

The main goal of this research direction is to develop new methods for synthesis of novel polymers — glycosilicones, which structure combine different fragments: hydrophobic and hydrophilic (polysiloxanes and poly/oligosaccharides), as well as to obtain materials based on them: next generation surfactants, drug dermal penetration enhancers, surface modificators in cosmetology and medicine and others. At the moment we have obtained cellulose-based glycosilicones that can be used to make facepowder.

Grant RFBR No. 19-33-90130. Project: «Directed macromolecular design of graft-copolymer hybrid structures based on polysiloxanes and saccharides» (Islamova R.M., Dobrynin M.V.). 2019–2021.

Carbohydr. Polym. 2020. V. 241. P. 116327. DOI: 10.1016/j.carbpol.2020.116327.

Publications

2023

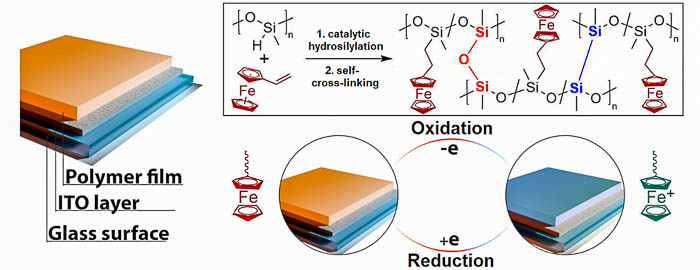

Deriabin K.V., Vereshchagin A.A., Kirichenko S.O., Rashevskii A.A., Levin O.V., Islamova R.M. Self-cross-linkable ferrocenyl-containing polysiloxanes as flexible electrochromic materials. Materials Today Chemistry. 2023. V. 29. Р. 101399. DOI: 10.1016/j.mtchem.2023.101399.

Abstract. Flexible ferrocenyl-containing silicone rubbers (FSRs) with various ferrocenyl-substituted unit contents of 25, 50, and 75 mol% were obtained by applying a simple method included catalytic hydrosilylation (between polymethylhydrosiloxane and vinylferrocene) and self-cross-linking reactions (dehydrocoupling between Si–H groups). Self-cross-linking is one of the most suitable and simple methods to coat and obtain FSRs on various contact conductive surfaces, such as onto indium tin oxide (ITO) glass or ITO-poly(ethylene terephthalate). The synthesized FSRs exhibit the electrochromic (EC) properties, resulting from the reduction-oxidation of ferrocenyl groups (Fc/Fc+ transformations at E0 c.a. 0.36 V) and leading to color change: oxidation causes new band formation at 634 nm in ultraviolet-visible spectra. FSRs with ferrocenyl-substituted unit content of 50 mol% (FSR50) is the most optimal in terms of EC (coloration efficiency of 10.98 cm2/C, coloring and bleaching times of c.a. 49 and 66 s, which are close to undoped oligoaniline-functionalized polysiloxanes and carbazolyl-modified polysiloxanes) and mechanical properties (the tensile strength, Young's modulus, and elongation at break are 2.80 MPa, 25.33 MPa, and c.a. 50%, respectively). The previously reported EC polysiloxanes have lack of mechanical characteristics. Both electrochromism and flexibility predominantly make FSR50 promising materials for the creation of flexible and stretchable EC devices.

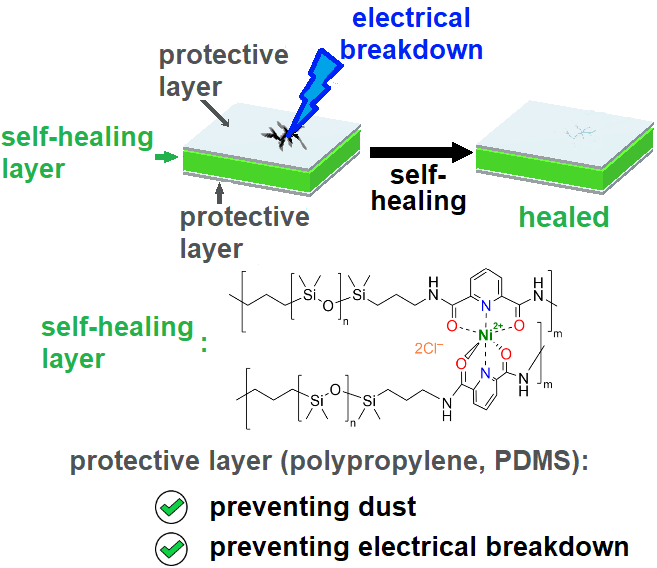

Deriabin K.V., Dziuba M.A., Rashevskii A.A., Kolesnikov I.E., Korzhov A.V., Sharov V.A., Vorob’ev A., Vereshchagin A.A., Chernukha A.S., Tian J., Levin O.V., Mukhin I.S., Islamova R.M. Nickel(II)-polysiloxane “sandwiches” as electrical breakdown protective materials. ACS Applied Polymer Materials. 2023, V. 5 (1), P. 892–898. DOI: 10.1021/acsapm.2c01822.

Abstract. Self-healing materials are an essential emerging class of smart materials, capable of repairing their damage after external stimuli, especially mechanical damages. However, the lack of studies on self-healing polymers after electrical breakdown is highly important for electrical engineering and electronics. We propose to use a nickel(II)-2,6-pyridinedicarboxamide-co-polydimethylsiloxane complex (NiPyPDMS) as an electrical breakdown protective material. To provide the absence of dust deposition from ambient air and to increase durability, we fabricated multilayered polymer “sandwiches” consisting of a NiPyPDMS layer covered with two films (polypropylene (PP) or polydimethylsiloxane (PDMS)) on both sides. Multilayered PP-NiPyPDMS-PP and PDMS-NiPyPDMS-PDMS films exhibit autonomous self-healing properties (up to 75%) after electrical breakdown at room temperature. NiPyPDMS demonstrates 3.7 times higher adhesion to copper, from which power lines are made, compared to PDMS. NiPyPDMS also exhibits antistatic and redox properties (NiII/NiIII transformations when electricity is applied). All characteristics mentioned above lead to reduce the probability of electrical breakdown via electrical charge dissipation in self-healing coating on possible power lines.

2022

Miroshnichenko A.S., Neplokh V., Mukhin I.S., Islamova R.M. Silicone materials for flexible optoelectronic devices. Materials. 2022, V. 15 (24), P. 8731. DOI: 10.3390/ma15248731. Review.

Abstract. Polysiloxanes and materials based on them (silicone materials) are of great interest in optoelectronics due to their high flexibility, good film-forming ability, and optical transparency. According to the literature, polysiloxanes are suggested to be very promising in the field of optoelectronics and could be employed in the composition of liquid crystal devices, computer memory drives organic light emitting diodes (OLED), and organic photovoltaic devices, including dye synthesized solar cells (DSSC). Polysiloxanes are also a promising material for novel optoectronic devices, such as LEDsbased on arrays of III–V nanowires (NWs). In this review, we analyze the currently existing types ofsilicone materials and their main properties, which are used in optoelectronic device development.

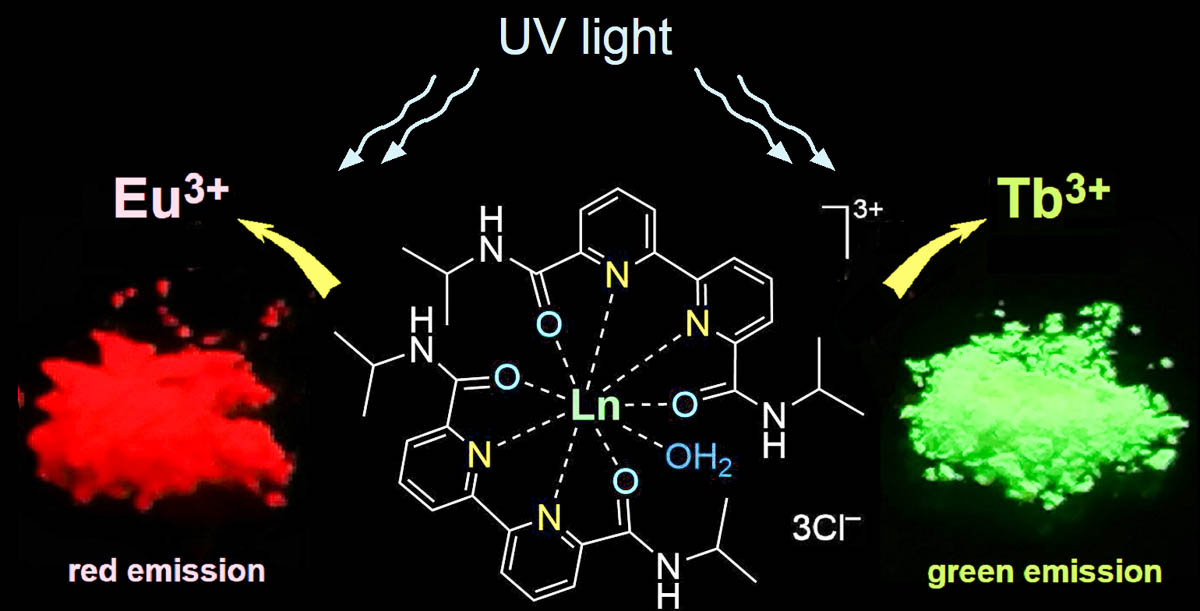

Miroshnichenko A.S., Deriabin K.V., Rashevskii A.A., Suslonov V.V., Novikov A.S., Mukhin I.S., Islamova R.M. Structural features of Eu3+ and Tb3+-bipyridinedicarboxamide complexes. Polymers. 2022. V. 14 (24). P. 5540. DOI: 10.3390/polym14245540.

Abstract. Photoluminescent lanthanide complexes of Eu3+ and Tb3+ as central atoms and N6, N6’-diisopropyl-[2,2′-bipyridine]-6,6′-dicarboxamide as ligand were synthesized. The structure of these complexes was established by single-crystal X-ray diffraction, mass spectrometry, 1H and 13C nuclear magnetic resonance, ultraviolet-visible, infrared spectroscopy, and thermogravimetry. Bipyridinic ligands provide formation of coordinatively saturated complexes of lanthanide ions and strong photoluminescence (PL). The Eu3+- and Tb3+-complexes exhibit PL emission in the red and green regions observed at a 340 nm excitation. The quantum yield for the complexes was revealed to be 36.5 and 12.6% for Tb3+- and Eu3+-complexes, respectively. These lanthanide compounds could be employed as photoluminescent solid-state compounds and as emitting fillers in polymer (for example, polyethylene glycol) photoluminescent materials.

Mikhail V. Dobrynin, Ilya V. Mongilev, Alexey A. Lezov, Igor Perevyazko, Peter M. Tolstoy, Yurii A. Anufrikov, Anna Yu. Shasherina, Petr S. Vlasov, Vadim Yu. Kukushkin and Regina M. Islamova. Block-copolymeric maltodextrin-based amphiphilic glycosilicones as surface-active systems. New J. Chem. 2022, V. 46, Р. 14849–14858. DOI: 10.1039/D2NJ02285K.

Abstract. Newly obtained amphiphilic glycosilicones are based on commercially available maltodextrins of various molecular weights (dextrose equivalent (DE) = 16.5–19.5 and 4–7) and hydride-terminated polydimethylsiloxane (Mw = 900). These carbohydrate polymers were synthesized via catalytic hydrosilylation employing Karstedt's catalyst, performed in benzene, between protected (by acetylation) and then modified (by allylation) maltodextrins with the hydride-terminated polydimethylsiloxane followed by deprotection. The block-copolymeric structure of the thus obtained glycosilicones was confirmed by 1H, 13C{1H}, and 29Si{1H} NMR spectroscopy. The carbohydrate polymers are soluble in water (<15 mg mL−1) and, in aqueous solutions, they form micelles, vesicles, and other aggregates with hydrodynamic radii spanning from 8 to 113 nm – as determined by dynamic light scattering, sedimentation experiments, and SEM. Titration calorimetry of glycosilicones based on maltodextrin demonstrates the critical micelle concentration of 13 mg mL−1 (ca. 10−3 mol L−1); these values are similar to those obtained for the commonly used alkylglucoside surfactants.

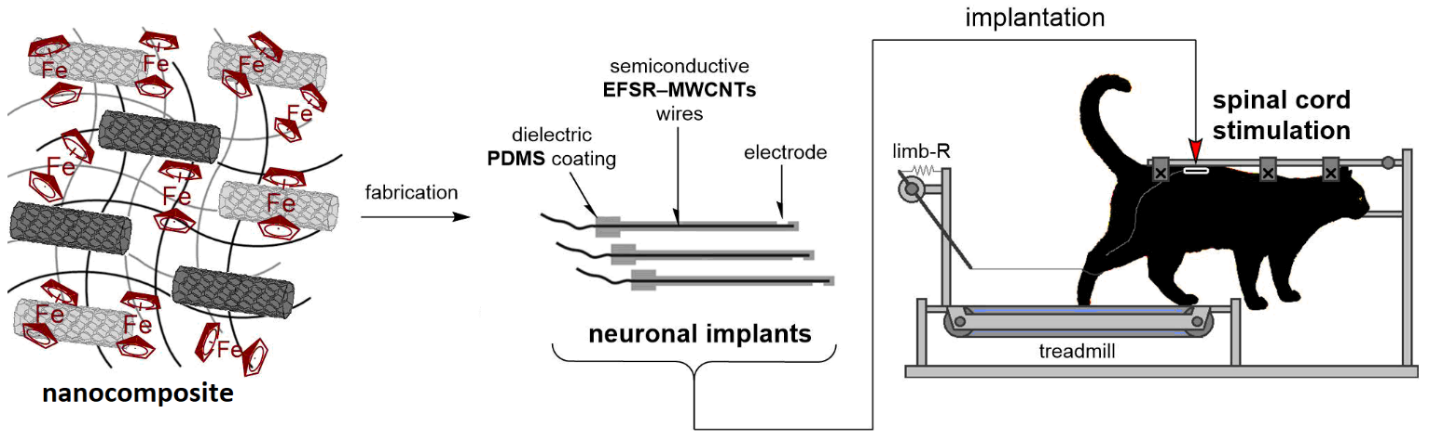

Deriabin K.V., Kirichenko S.O., Lopachev A.V., Sysoev Yu., Musienko P.E., Islamova R.M. Ferrocenyl-containing silicone nanocomposites as materials for neuronal interfaces. Composites Part B: Engineering. 2022, V. 236, P. 109838. DOI: 10.1016/j.compositesb.2022.109838.

Abstract. A synthetic method involving hydrosilylation reactions was developed to produce nanocomposites of elastic ferrocenyl-containing silicone rubber (EFSR) and multi-walled carbon nanotubes (MWCNT). The EFSR-MWCNT nanocomposites have a satisfactory elongation at break ∼80%, tensile strength (2.4 MPa), as well as electrical conductivity comparable to that of semiconductors (7∙10−5 S·cm−1), all of which are necessary for application as neuronal implants. A novel prototype of a spinal cord neuronal interface based on EFSR-MWCNT was created as a prosthetic for impaired neuronal functions and to access spinal sensorimotor networks. Ferrocenyl groups in nanocomposites increase the charge injection that declines the risks of negative effects of electrical stimulation including nerve tissue damage.

Miroshnichenko A., Deriabin K.V., Dobrynin M.V., Baranov A., Neplokh V., Mitin D., Kolesnikov I.E., Parshina E.K., Mukhin I.S., Islamova R.M. Lanthanide(ΙΙΙ)-incorporating polysiloxanes as materials for light-emitting devices. ACS Applied Polymer Materials. 2022, V. 4 (4), P 2683-2690. DOI: 10.1021/acsapm.2c00017.

Abstract. Light-excited flexible and self-healing luminescent polymers have attracted extensive attention for developing advanced color-emitting films. Luminophores on the base of lanthanide(III)-incorporating polysiloxanes exhibit a high photoresponse and can be applied for controlled color lighting in flexible device applications. We present red-, green-, and blue-emitting Eu3+, Tb3+, and Tm3+-bipyridinedicarboxamide-co-polydimethylsiloxanes (Ln-Bipy-PDMS) produced with a two-step procedure of polycondensation and complexation. Bipyridinic ligands provide formation of coordinatively saturated complexes of lanthanide ions and strong photoluminescence (PL) in the case of Eu3+ and Tb3+. The thin Ln-Bipy-PDMS films are studied as ultraviolet-light converters, which can be mechanically stacked one above another to achieve the desired color. We demonstrate that these stacks can have intense PL in the spectral range from green to yellow and red. Due to the structural features, Ln-Bipy-PDMS also demonstrate a relatively high tensile (approximately 1.5 MPa) and elongation at break (approximately 185%) and non-autonomous self-healing on heating. The self-healing properties of Ln-Bipy-PDMS enable the stacking of films into monoliths with the required color of PL. Such systems do not require any synthesis stages, and a one-healed monolith film possesses two luminescence colors.

2021

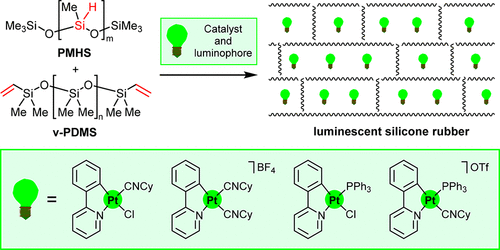

Dobrynin M.V., Kasatkina S.O., Baykov S.V., Savko P.Y., Antonov N.S., Mikherdov A.S., Boyarskiy V.P. and Islamova R.M. Deprotonated diaminocarbene platinum complexes for thermoresponsive luminescent silicone materials: both catalysts and luminophores. Dalton Trans. 2021, V. 50 (42), P. 14994–14999. DOI: 10.1039/D1DT02823E.

|

Abstract. C,N-Chelate deprotonated diaminocarbene platinum(II) complexes were synthesized by coupling coordinated isocyanides and azinyl-substituted ureas. The complexes act as catalysts of α,ω-divinylpolydimethylsiloxane and poly(dimethylsiloxane-co-methylhydrosiloxane) hydrosilylation cross-linking. Silicone rubbers obtained with (aminoisoquinoline)-containing complex 3d exhibit temperature-responsive luminescence. Their emission changes irreversibly when heated from 80–100 °C (green radiation) to 120 °C or more (blue radiation). |

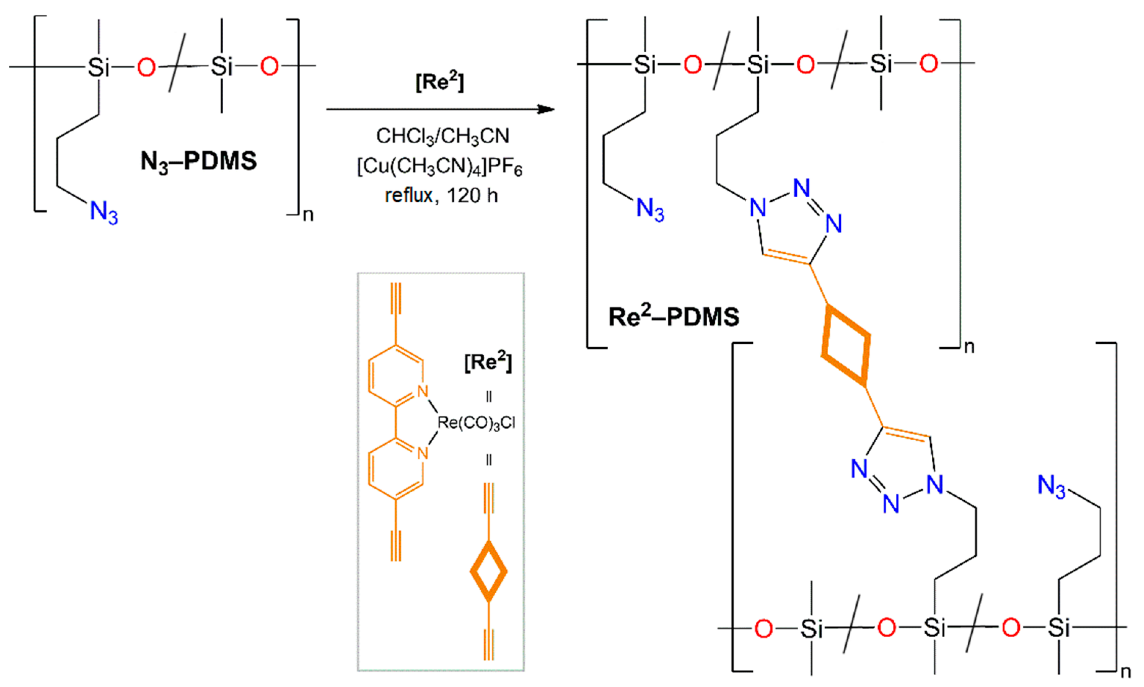

Baranovskii E.M., Khistiaeva V.V, Deriabin K.V., Petrovskii S.K., Koshevoy I.O., Kolesnikov I.E., Grachova E.V., Islamova R.M. Re(I) complexes as backbone substituents and cross-linking agents for hybrid luminescent polysiloxanes and silicone rubbers. Molecules. 2021, V. 26 (22), 6866. DOI: 10.3390/molecules26226866.

Abstract. This study focuses on the synthesis of hybrid luminescent polysiloxanes and silicone rubbers grafted by organometallic rhenium(I) complexes using Cu(I)-catalyzed azido-alkyne cycloaddition (CuAAC). The design of the rhenium(I) complexes includes using a diimine ligand to create an MLCT luminescent center and the introduction of a triple C≡C bond on the periphery of the ligand environment to provide click-reaction capability. Poly(3-azidopropylmethylsiloxane-co-dimethylsiloxane) (N3-PDMS) was synthesized for incorporation of azide function in polysiloxane chain. [Re(CO)3(MeCN)(5-(4-ethynylphenyl)-2,2′-bipyridine)]OTf (Re1) luminescent complex was used to prepare a luminescent copolymer with N3-PDMS (Re1-PDMS), while [Re(CO)3Cl(5,5′-diethynyl-2,2′-bipyridine)] (Re2) was used as a luminescent cross-linking agent of N3-PDMS to obtain luminescent silicone rubber (Re2-PDMS). The examination of photophysical properties of the hybrid polymer materials obtained show that emission profile of Re(I) moiety remains unchanged and metallocenter allows to control the creation of polysiloxane-based materials with specified properties.

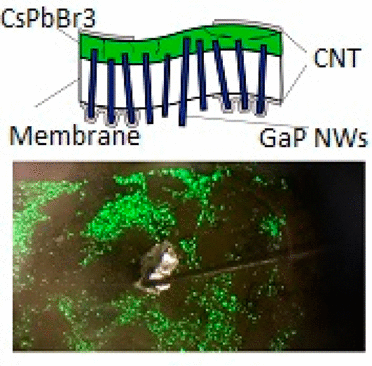

Miroshnichenko A.S., Deriabin K.V., Baeva M., Kochetkov F.M., Neplokh V., Fedorov V.V., Mozharov A.M., Koval O.Yu., Krasnikov D.V., Sharov V.A., Filatov N.A., Gets D.S., Nasibulin A.G., Makarov S.V., Mukhin I.S., Kukushkin V.Yu., Islamova R.M Flexible Perovskite CsPbBr3 Light Emitting Devices Integrated with GaP Nanowire Arrays in Highly Transparent and Durable Functionalized Silicones. J. Phys. Chem. Lett. 2021, V. 12, P. 9672−9676. DOI: 10.1021/acs.jpclett.1c02611.

|

Abstract. The architecture of transparent contacts is of utmost importance for creation of efficient flexible light-emitting devices (LEDs) and other deformable electronic devices. We successfully combined the newly synthesized transparent and durable silicone rubbers and the semiconductor materials with original fabrication methods to design LEDs and demonstrate their significant flexibility. We developed electrodes based on a composite GaP nanowire–phenylethyl-functionalized silicone rubber membrane, improved with single-walled carbon nanotube films for a hybrid poly(ethylene oxide)–metal–halide perovskite (CsPbBr3) flexible green LED. The proposed approach provides a novel platform for fabrication of flexible hybrid optoelectronic devices. |

Deriabin K.V., Ignatova N.A., Kirichenko S.O., Novikov A.S., Kryukova M.A., Kukushkin V.Yu., Islamova R.M. Structural Features of Polymer Ligand Environments Dramatically Affect the Mechanical and Room-Temperature Self-Healing Properties of Cobalt(II)-Incorporating Polysiloxanes. Organometallics. 2021, V. 40 (15), P. 2750–2760. DOI: 10.1021/acs.organomet.1c00392.

Abstract. Cobalt(II)-pyridinedicarboxamide-co-polydimethylsiloxane (Co-Py-PDMSs) and cobalt(II)-bipyridinedicarboxamide-co-polydimethylsiloxane (Co-Bipy-PDMSs) polymer–metal complexes were prepared by complexation between Py-PDMSs or Bipy-PDMSs ligands and cobalt(II); the metal content in these complexes varied from 0.09 to 2.41 wt %. The CoII binding patterns (the Co–NPy and Co–O coordination in Co-Py-PDMSs and Co–NBipy in Co-Bipy-PDMSs) were established by UV–vis and IR methods and by comparison with model CoII complexes exhibiting relevant O,N,O- and N,N-coordination environments, respectively. The mechanical properties of the polymer–metal complexes were controlled by the coordination of Py-PDMSs or Bipy-PDMSs to CoII at various metal-to-ligand molar ratios (1:(1–6)) and by the variation of the polydimethylsiloxane unit length (Mn: 850–900, 5000, or 25 000 g·mol–1). Utilization of the chelated Py-PDMSs and Bipy-PDMSs polymer ligands, which are capable of tri- or bidentate binding of CoII, led to (2–4)-fold increases in tensile strength (up to 1.75 MPa) and much higher elongation at break ((2–3)-fold increase up to 2100%) compared with the previously reported CoII-based polymer–ligand systems featuring monodentate ligation entities. Changing the main-chain ligand from Py-PDMSs to Bipy-PDMSs led to an increase in tensile strength of (2–4)-fold in comparison with Py-PDMS and a lower hysteresis (4%). The room temperature self-healing efficiency was up to 96% for Co-Py-PDMSs and 40% for Co-Bipy-PDMSs, as measured for a polydimethylsiloxane unit with Mn = 25 000 g·mol–1.

Dobrynin M.V., Sokolova E.V., Kinzhalov M.A., Smirnov A.S., Starova G.L., Kukushkin V.Yu., and Islamova R.M. Cyclometalated Platinum(II) Complexes Simultaneously Catalyze the Cross-Linking of Polysiloxanes and Function as Luminophores. ACS Appl. Polym. Mater. 2021, V. 3 (2), P. 857–866. DOI: 10.1021/acsapm.0c01190.

Abstract. A family of the C,N-cyclometalated species [Pt(ppy)Cl(PPh3)], [Pt(ppy)Cl(CNCy)], [Pt(ppy)(CNCy)(PPh3)](OTf), and [Pt(ppy)(CNCy)2](BF4) (ppy = 2-phenylpyridinato-C2,N; Cy = cyclohexyl) was generated from [Pt(ppy)(μ-Cl)]2, CNCy, and PPh3. The obtained platinum(II) complexes were characterized by high-resolution ESI+-MS, IR, and 1D (1H, 13C{1H}, 195Pt{1H}) and 2D (1H,1H-NOESY; 1H,13C-HSQC; 1H,13C-HMBC) NMR spectroscopy, and the latter three complexes were investigated by X-ray diffraction. All four platinum species were examined as hydrosilylation catalysts (c 10–4–10–3 M; 80–120 °C; [Pt(ppy)Cl(PPh3)] exhibited the highest catalytic activity) for the cross-linking of vinyl-terminated polydimethylsiloxane and polymethylhydrosiloxane to achieve luminescent silicone rubbers. Each solid complex and the appropriate silicone rubber exhibited the same emission spectra in the green region and strong phosphorescence with a solid-state quantum yield of up to 12.5% (measured for the silicone elastomer obtained with the [Pt(ppy)(CNCy)2](BF4) catalyst). The resulting luminescent silicone rubbers can be potentially used for protective coatings (to facilitate the thickness control) and as a component for phosphor-converted white light-emitting diodes (to transform a UV part of the LED emission to the visible spectrum).

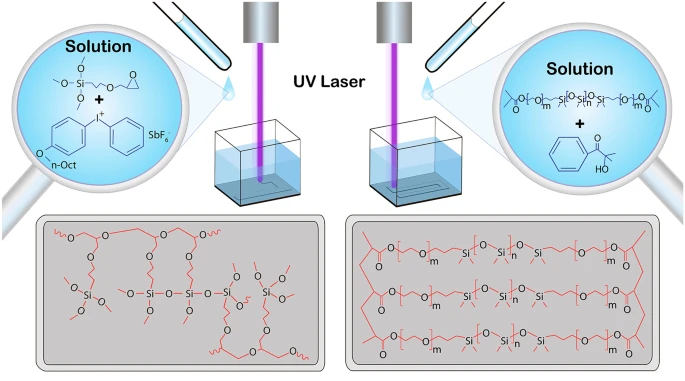

Talianvov P.M., Rzhevskii S.S., Pankin D.V., Deriabin K.V., Islamova R.M., Manshina A.A. Structural features of functional polysiloxanes radical and ionic photo-curing for laser printing applications. J. Polym. Res. 2021, V. 28 (2), P. 37. DOI: 10.1007/s10965-021-02409-0

.

.

Abstract. The laser induced curing of acryloxy terminated ethyleneoxide dimethylsiloxane-ethyleneoxide ABA block copolymer (PDMS-AO) and (3-glycidoxypropyl)trimethoxysilane (GPTMS) was carried out with 2-hydroxy-2-methylpropiophenone as radical photoinitiator and p-(octyloxyphenyl)phenyliodonium hexafluoroantimonate as cationic photoinitiator, respectively. The cross-linking mechanisms for both mixtures were determined through monitoring of photocuring by SSNMR, FTIR and Raman spectroscopies. The obtained silicone rubbers were tested by swelling measurements and thermogravimetric analysis. In comparison with PDMS-AO, cross-linked GPTMS had slightly more cross-linking density (by approximately 20% more). The cross-linked GPTMS was more thermally stable in air than cured PDMS-AO (by c.a. 190° C) due to both mechanisms: epoxy polymerization and Si–O–Si formation. The possibility of laser printing with defined framework for PDMS-AO was successfully demonstrated that allows obtaining laser printed polymer objects.

2015–2020

- Deriabin K.V., Ignatova N.A., Kirichenko S.O., Novikov A.S., and Islamova R.M. Nickel(II)-pyridinedicarboxamide-co-polydimethylsiloxane complexes as elastic self-healing silicone materials with reversible coordination. Polymer. 2020, P. 123119. DOI: 10.1016/j.polymer.2020.123119.

- Deriabin K.V., Dobrynin M.V., and Islamova R.M. A metal-free radical technique for cross-linking of polymethylhydrosiloxane or polymethylvinylsiloxane using AIBN. Dalton Trans. 2020, V. 49, P. 8855–8858. DOI: 10.1039/D0DT01061H.

- Dobrynin M.V., Kukushkin V.Y., and Islamova R.M. Cellulose-based hybrid glycosilicones via grafted-to metal-catalyzed hydrosilylation: “When opposites unite”. Carbohydr. Polym. 2020, V. 241, P. 116327. DOI: 10.1016/j.carbpol.2020.116327.

- Neplokh V., Kochetkov F.M., Deriabin K.V., Fedorov V.V., Bolshakov A.D., Eliseev I.E., Mikhailovskii V.Y., Ilatovskii D.A., Krasnikov D.V., Tchernycheva M., Cirlin G., Nasibulin A.G., Mukhin I.S., and Islamova R.M. Modified silicone rubber for fabrication and contacting of flexible suspended membranes of n-/p-GaP nanowires with a single-walled carbon nanotube transparent contact. J. Mater. Chem. C. 2020, V. 8, P. 3764–3772. DOI: 10.1039/C9TC06239D.

- Dobrynin, M.V, Pretorius, C., Dumisani V.K., Roodt, A., Boyarskiy, V.P., and Islamova, R.M. Rhodium(I)-catalysed cross-linking of polysiloxanes conducted at room temperature. J. Catal. 2019, V. 372, P. 193–200. DOI: 10.1016/j.jcat.2019.03.004.

- Deriabin, K.V., Lobanovskaia, E.K., Kirichenko S.O., Barshutina, M.N., Musienko, P.E., and Islamova, R.M. Synthesis of ferrocenyl-containing silicone rubbers via platinum-catalyzed Si–H self-cross-linking. Appl. Organomet. Chem. 2019, V. 34, P. e5300. DOI: 10.1002/aoc.5300.

- Deriabin, K.V., Lobanovskaia, E.K., Novikov, A.S., and Islamova, R.M. Platinum-catalyzed reactions between Si–H groups as a new method for cross-linking of silicones. Org. Biomol. Chem. 2019, V. 17, P. 5545–5549. DOI: 10.1039/C9OB00791A.

- Deriabin, K. V., Yaremenko, I. A., Chislov, M. V., Fleury, F., Terent’ev, A. O., and Islamova, R. M. Similar nature leads to improved properties: cyclic organosilicon triperoxides as promising curing agents for liquid polysiloxanes. New J. Chem. 2018, V. 42 (18), P. 15006–15013. DOI: 10.1039/C8NJ02499E.

- Islamova R.M., Dobrynin M.B., Vlasov A.V., Eremina A.A., Kinzhalov M.A., Kolesnikov I.E., Zolotarev A.A., Masloborodova E.A., and Luzyanin K.V. Iridium(III)-catalysed cross-linking of polysiloxanes leading to the thermally resistant luminescent silicone rubbers. Catal. Sci. Technol. 2017, V. 7 (24), P. 5843-5846. DOI: 10.1039/c7cy02013a.

- Masloborodova E.A., Kaganova E.V., Gusakova N.S., Agibalova L.V., Maretina E.Yu., Baranets I.V., Islamova R.M. Effect of ferrocene on the synthesis of graft copolymers of vinylpolysiloxane and styrene. Rus. J. Gen. Chem. 2017, V. 87 (5), Р. 1038–1046. DOI: 10.1134/S1070363217050243.

- Islamova R.M., Dobrynin M.V., Ivanov D.M., Vlasov A.V., Kaganova E.V., Grigoryan G.V., Kukushkin V.Yu. bis-Nitrile and bis-Dialkylcyanamide Platinum(II) Complexes as Efficient Catalysts for Hydrosilylation Cross-Linking of Siloxane Polymers. Molecules. 2016, V. 21 (3), P. 311-321. DOI: 10.3390/molecules21030311.

- Islamova R.M. Iron compounds in controlled radical polymerization: Ferrocenes, (clathro)chelates, and porphyrins. Rus. J. Gen. Chem. 2016, V. 86 (1), P. 125-143. DOI: 10.1134/S1070363216010217.

- Demakova M.Ya., Bolotin D.S., Bokach N.A., Islamova R.M., Starova G.L., Kukushkin V.Yu. Click-Type PtII-Mediated Hydroxyguanidine–Nitrile Coupling Provides Useful Catalysts for Hydrosilylation Cross-Linking. ChemPlusChem. 2015, V. 80 (11), Р. 1607-1614. DOI: 10.1002/cplu.201500327.

- Islamova R.M., Vlasov A.V., Dobrynin M.V., Masloborodova E.A., Kaganova E.V. Two-component catalytic systems based on platinum(II) and platinum(0) complexes for hydrosilylation of polysiloxanes. Rus. J. Gen. Chem. 2015, V. 85 (11), Р. 2609–2613. DOI: 10.1134/S1070363215110171.

Grants

- Grant RSF No. 23-23-00103 (grant owner: Deriabin K.V.), 2023–2024.

- Grant SPBU (grant owner: Islamova R.M.), 2022–2024.

- Grant RSF No. 20-19-00256 (grant owner: Islamova R.M.), 2020–2022.

- Grant RFBR No. 19-33-90130 (grant owner: Islamova R.M.), 2019–2021.

- Grant RFBR No. 19-33-90134 (grant owner: Islamova R.M.), 2019–2021.

- Grant RFBR No. 18-33-20062 (grant owner: Islamova R.M.), 2019–2020.

- Grant RFBR No. 18-33-00769 mol_a (grant owner: Dobrynin M.V.), 2018–2019.

- Grant RFBR No. 14-03-00260-а (grant owner: Islamova R.M.), 2014–2016.

Information for students and postgraduates

We invite students, postgraduates and young scientists to perform final qualifying and dissertation works in our scientific group.

Contacts: professor Regina Islamova, This email address is being protected from spambots. You need JavaScript enabled to view it.